NEWS

- Time of issue:2023-07-20

Advantages of titanium alloy auto parts

(Summary description)

Advantages of titanium alloy auto parts

(Summary description)

- Categories:News Center

- Author:

- Origin:

- Time of issue:2023-07-20 09:25

- Views:

Common titanium alloy auto parts:

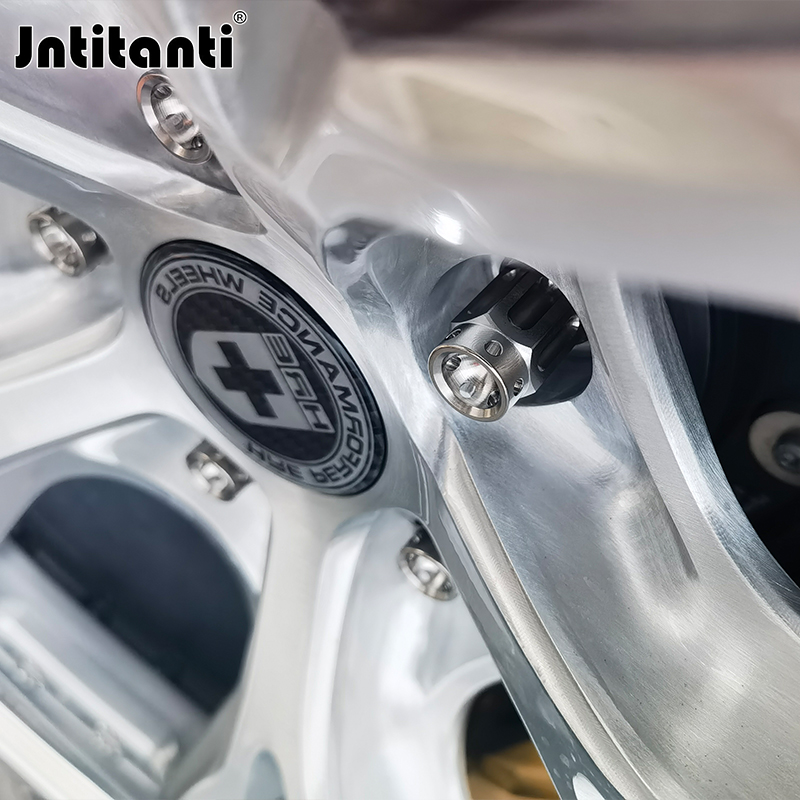

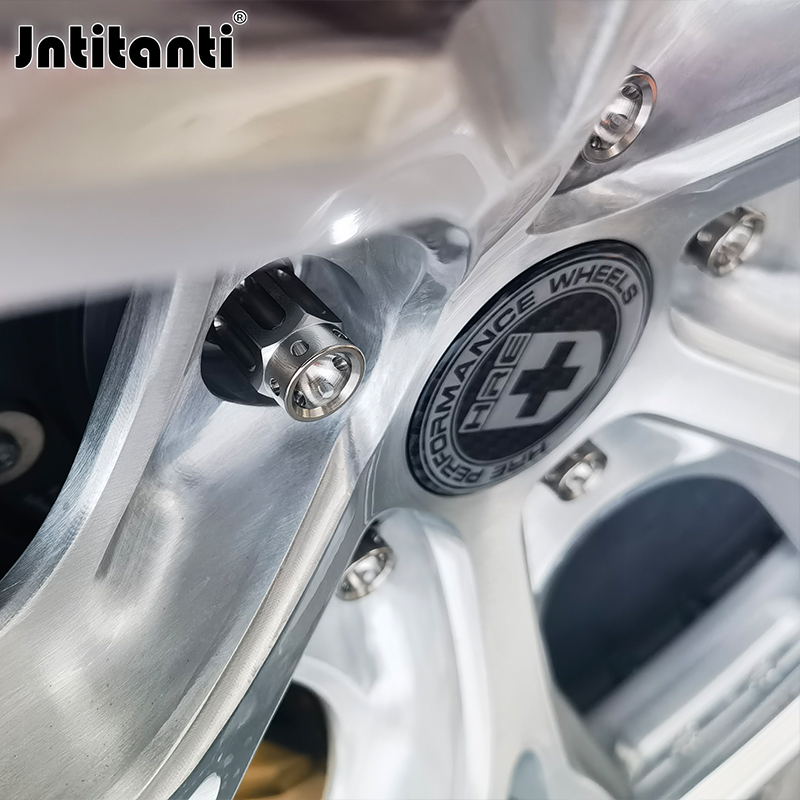

1, titanium alloy hub bolt - titanium alloy bolt is an essential part of the modified hub, not only light weight, strength is higher than steel bolts. The unique luster is also a good decoration on the wheel hub, improving the appearance level.

2, engine valve - titanium alloy automobile engine valve light weight, long service life, but also reduce fuel consumption. Compared with the steel engine valve, the mass is reduced by about 30%-40%, and the engine limit speed can be increased by about 20%.

3, valve spring seat - the advantages of high strength and fatigue resistance of titanium alloy just match the characteristics of the valve spring seat, titanium alloy valve spring seat than the steel mass reduced by 30%-40%, so that the valve structure reduces the inertia mass, the maximum engine speed can also be increased.

4, titanium alloy spring - titanium alloy has a low elastic modulus, compared with steel spring, under the premise of providing the same elasticity, the height of titanium spring is only 40% of the steel spring, the mass is only 30%-40% of the steel spring, to the body to bring greater design space. In addition, the service life of titanium alloy springs is much longer than that of steel.

5, turbocharger transfer rotor - titanium alloy has good heat resistance, and good processing type. The transfer rotor of the turbocharger works in an environment of 850 ° C for a long time, which gives the titanium alloy a good space to play.

6, exhaust system and muffler - titanium alloy is widely used in the automobile exhaust system, performance, life extension and appearance have been improved, improve fuel combustion efficiency. Titanium exhaust system than steel exhaust, the mass can be reduced by about 40%, generally about 5 kg of mass.

7, the body frame - some titanium alloy high strength, good toughness, is the ideal material for making the body frame. Japanese car manufacturers use titanium to make body frames for a better driving experience.

8, titanium alloy engine connecting rod - Titanium alloy with its lightweight advantages, the material used as the connecting rod is very rational. Compared with steel links, titanium links can reduce the weight of 15%-20%. The first car to use titanium rods was the Ferrari 315LV8.

9, other titanium alloy parts - In addition to the above parts, titanium is also used in engine rocker arm, suspension spring, engine piston pin, car fasteners, hanging ear nuts, car door burst beam, car stop bracket, brake caliper piston, pin bolt, pressure plate, shift button and car clutch round plate and other auto parts.

Scan the QR code to read on your phone

Other information

TEL

Email : titan@jntitan.cn

Address: After-sales Service, No.2966 Airport Road, Licheng District, Jinan City, Shandong Province